What are High-Solids Eco-Friendly Coatings?

With the development of society and the economy, people's demand for green and environmentally friendly solutions continues to grow, and coating products are no exception. Currently, high-solids, solvent-free coatings are the mainstream approach for developing green coatings internationally. So what exactly is a high-solids coating? What are the advantages of polyaspartic polyurea when applied to high-solids coatings?

What is a High-Solids Coating?

High-solids coatings are coatings with high solid content and relative molecular weight, often abbreviated as HSC (High-Solids Coating). These coatings typically have a solid content of 65%, 85%, or even higher. The most environmentally friendly high-solids coatings are solvent-free. High-solids coatings are widely used in industries such as light manufacturing, handicrafts, textiles, electromechanical equipment, instrumentation, and engineering machinery coatings.

Why Choose High-Solids Environmentally Friendly Coatings?

High-solids, low-solvent coating systems support advanced exhaust gas management and solvent recycling, allowing VOC emissions to be controlled below 10g/m³ to meet the strictest VOC regulations. This makes high-solids coatings a cost-effective choice for traditional coatings companies, heavy-duty anticorrosion engineering, and marine ship applications.

The main resins used in high-solids environmentally friendly coatings include: polyaspartic polyurea resin (polyaspartic resin), high-solid polyester resin, high-solid acrylic resin, high-solid polyurethane resin, and high-solid alkyd resin. The molecular structure determines the properties of these resins, allowing them to achieve viscosities of 1000-1500mPas. Common types, such as acrylic, polyurethane, and alkyd resins, typically have a solid content of 70-80%. In room temperature self-curing systems, polyaspartic resin combined with solvent-free, low-viscosity isocyanates is one of the few construction materials that can achieve 100% solids without any solvent.

Unique Properties and Application Prospects of Polyaspartic

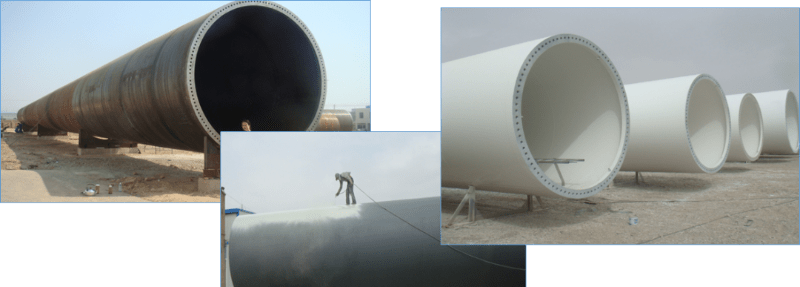

Polyaspartic is known for its low-temperature curing, exceptional abrasion resistance, and high weather resistance. These unique properties make it suitable for a wide range of applications, including petroleum and petrochemical anticorrosion coatings, marine coatings, wind turbine blade coatings, and automotive coatings. As labor costs and raw material prices continue to rise, profit margins for companies are being squeezed. The future trend not only requires low VOC emissions but also demands high anticorrosive performance, compliance with environmental regulations, improved construction efficiency, and reduced coating costs. Therefore, high-solids coatings are expected to gain a larger market share in the future.

Feiyang Protech has been specializing in the production of raw materials for polyaspartic coatings for 30 years and can provide polyaspartic resins, hardeners and coating formulations. Feel free to contact us: marketing@feiyang.com.cn

Our products list:

Contact our technical team today to explore how Feiyang Protech’s advanced polyaspartic solutions can transform your coatings strategy. Contact our Tech Team