Polyaspartic Waterproof Coating: Superior Solution for Exterior Walls

With economic and social advancements, people's expectations for building quality, safety, and durability are rising.

This is evident not only in enhanced living comfort but also in improved building waterproofing systems.

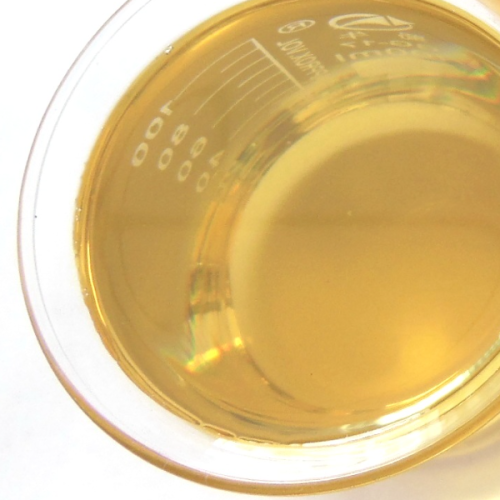

The exterior wall transparent polyaspartic waterproof coating is made by reacting high-purity polyaspartic resin with isocyanate prepolymer. This creates a durable and transparent waterproof layer.

It adheres directly to substrates like wall tiles, resisting peeling, surface powdering, or blister formation.

This product provides long-lasting waterproof protection, excellent weather resistance, strong adhesion, flexibility, abrasion resistance, crack resistance, and eco-friendliness. It effectively prevents water seepage, ensuring a reliable and extended service life for wall surfaces.

Advantages of Polyaspartic Waterproof Coating

- The coating is colorless and transparent, maintaining the original decorative appearance without yellowing. It is washable, dirt-resistant, and offers anti-corrosion and anti-mold properties.

- Features rapid film formation, strong adhesion, and excellent overall encapsulation.

- Provides high transparency, yellowing resistance, and outstanding weather and acid-alkali resistance.

- Can be applied at 0°C, cures normally at -5°C, is safe to operate, easy to apply, and compatible with direct painting, brushing, or troweling on the wall.

- No tile removal is required, ensuring low material usage and reduced application costs.

Application Range

- Suitable for waterproofing repairs on building exterior walls, balconies, and surfaces such as wall tiles, marble, and granite, offering anti-corrosion and water-resistant protection.

- Provides anti-corrosion and waterproof coatings for inorganic materials such as cement, ceramics, and glass.

- Ideal for decorative waterproofing and anti-corrosion on balconies, roof walls (both new and old), and areas with intricate designs.

Application Method

- The substrate must be thoroughly cleaned to ensure it is dry, oil-free, and dust-free. Follow the specified mixing ratios as instructed.

- The coating should be free of missed spots, delamination, lifted edges, or cracks. Reapply promptly to any insufficiently covered areas.

Precautions

- During application, ensure the product fully covers the substrate. Allow 24 hours for curing before performing any additional work.

- For areas requiring high abrasion resistance, apply an additional layer of wear-resistant waterproof material to protect the coating.

Feiyang Protech has been specializing in the production of raw materials for polyaspartic coatings for 30 years and can provide polyaspartic resins, hardeners and coating formulations. Feel free to contact us: marketing@feiyang.com.cn

Our products list:

Contact our technical team today to explore how Feiyang Protech’s advanced polyaspartic solutions can transform your coatings strategy. Contact our Tech Team