How to Calculate the Amount of Polyaspartic Polyurea Resin and Hardener?

Polyaspartic polyurea, known for its excellent performance, is widely used in waterproofing, anti-corrosion, flooring, adhesives, and other fields. However, many engineers face a common question when they begin designing coating formulations with polyaspartic polyurea resin: How should the amounts of polyaspartic polyurea resin and curing agent be calculated? Today, we will provide a detailed explanation of the methods involved.

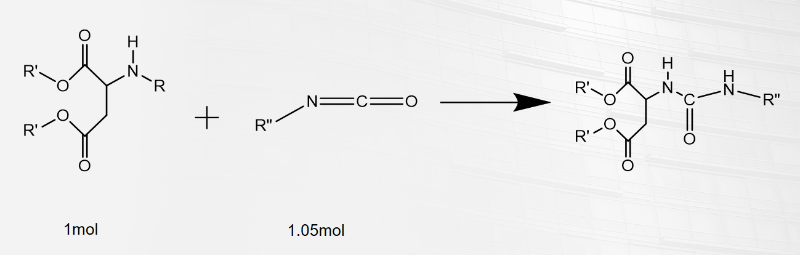

To address this problem, we first need to understand the reaction principle between polyaspartic resin and the curing agent. The secondary amine groups in the polyaspartic polyurea resin react with the isocyanate curing agent to form a polymer with urea bonds. Due to the high bond energy of urea, the resulting polyaspartic polyurea resin film exhibits excellent properties, including high strength, wear resistance, impact resistance, flexibility, weather resistance, and chemical resistance.

The equivalent value refers to the mass of resin needed to provide 1 mol of reactive groups. This can be understood as the mass of resin required to provide 1 mol of secondary amine groups (-NH) in the polyaspartic ester resin. For example, the equivalent value of F420 is 277 g/mol.

The isocyanate component in isocyanates is usually expressed as the percentage of isocyanate mass (NCO%), which can also be represented in terms of equivalents. This is defined as the number of grams of isocyanate required to react with 1 gram of molecular amine to form the corresponding urea. The relationship between equivalents and the percent isocyanate content is expressed as follows: equivalents = 42 / NCO%.

Calculation of the Amount of Polyaspartic Polyurea Resin and Hardener

According to the principle of equivalency, 1 mol of -NH requires 1 mol of -NCO for complete curing. To ensure sufficient curing, a 5% excess of the curing agent is recommended. For example, using HT-600 as the curing agent, with an NCO value of 23%, the equivalent is calculated as 4200 / 23 ≈ 183 g/mol. Therefore, to cure 100 g of F420, the amount of HT-600 required can be calculated as follows: (100/277)×1.05×183≈69.4g.

Feiyang Protech has been specializing in the production of raw materials for polyaspartic coatings for 30 years and can provide polyaspartic resins, hardeners and coating formulations. Feel free to contact us: marketing@feiyang.com.cn

Our products list:

Contact our technical team today to explore how Feiyang Protech’s advanced polyaspartic solutions can transform your coatings strategy. Contact our Tech Team