Application of Polyaspartic Resin in the Preparation of High-Solid Acrylic Polyurethane Coatings

The concept of achieving carbon neutrality and carbon peak goals (dual-carbon goals) highlights China's commitment as a global leader and is prompting a transformation across Chinese industries, with carbon emission management becoming a central focus. For companies specializing in coatings, developing new products now prioritizes performance enhancement alongside minimizing volatile organic compounds (VOCs).

Acrylic polyurethane coatings are widely used for outdoor anti-corrosion topcoats. However, some resins currently in use have low solid content, leading to insufficient film thickness and environmental pollution due to the release of organic volatiles. Although technological advances have introduced hydroxypropyl resins with 80% solid content, their high viscosity and low reactivity still require substantial solvent use. Thus, the coating may still have up to 70% solids, releasing significant VOC levels.

Polyaspartic ester resin, commonly known as polyaspartic resin, is a solvent-free, low-viscosity material that demonstrates excellent weather, corrosion, and abrasion resistance. In recent years, it has gained traction in various applications, such as waterproofing, anti-corrosion, and flooring.

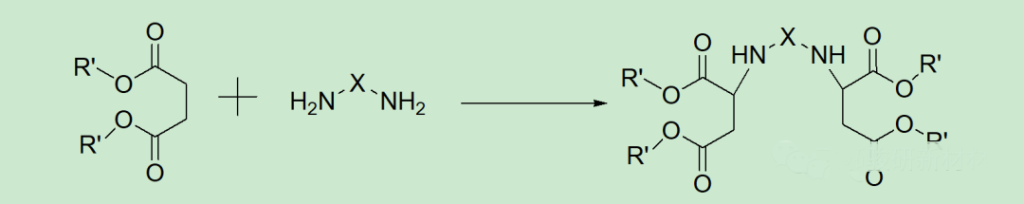

Chemically, polyaspartic resin is an aliphatic secondary amine, a material synthesized through the Michael addition of maleic acid esters and primary diamines. The synthesis principle is illustrated in the figure below:

Reaction principle of polyaspartic resin synthesis

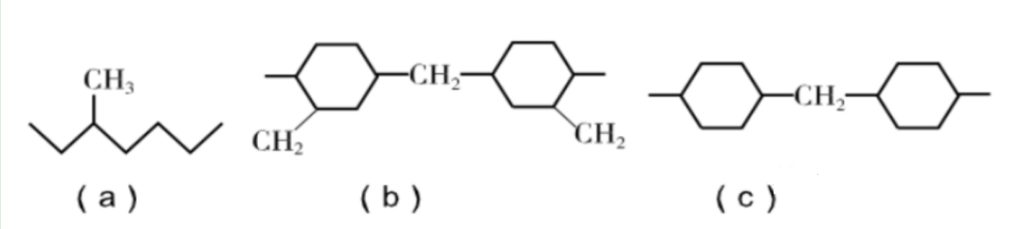

With various diamine main chain structures (X) available, common polyaspartic resin main chain (X) structures include the following:

Polyaspartic resin main chain (X) structure

The performance of acrylic polyurethane coatings can be tailored to meet various requirements by selecting polyaspartic resins with different characteristics. Generally, polyaspartic resins offer the following advantages when used in an acrylic polyurethane system:

1.Reduction of Viscosity and VOC Content:

Polyaspartic resin typically has a solid content of about 96% and is compatible with hydroxypropyl resin. When incorporated into hydroxypropyl-based coatings, it can increase the system's solid content, reaching up to 85% during application. As a low-viscosity amine compound with molecular viscosities ranging from 60 cps to 1000 cps, polyaspartic resin effectively dilutes the coating mixture, thus reducing VOC levels and enhancing film thickness.

2.Accelerated Drying Speed:

Acrylic polyurethane coatings usually take around 24 hours to dry. Under low temperatures or low hydroxyl activity, high-temperature curing is often required. Polyaspartic resin, when combined with HDI trimers, has a gel time ranging from 2 to 130 minutes. Its molecular structure includes a sterically hindered secondary amino group, which is more reactive than hydroxyl groups. When blended with hydroxypropyl resin, it speeds up the drying process, achieving sufficient hardness for sanding and polishing within a few hours. Even at low temperatures (-15°C), the coating can air-dry without baking, conserving energy and reducing emissions.

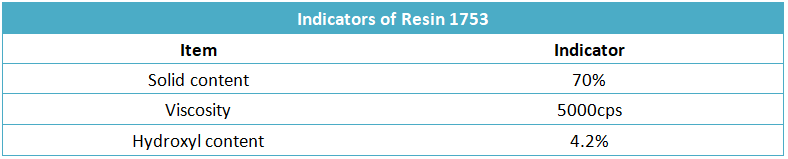

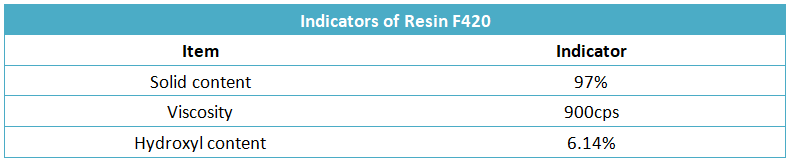

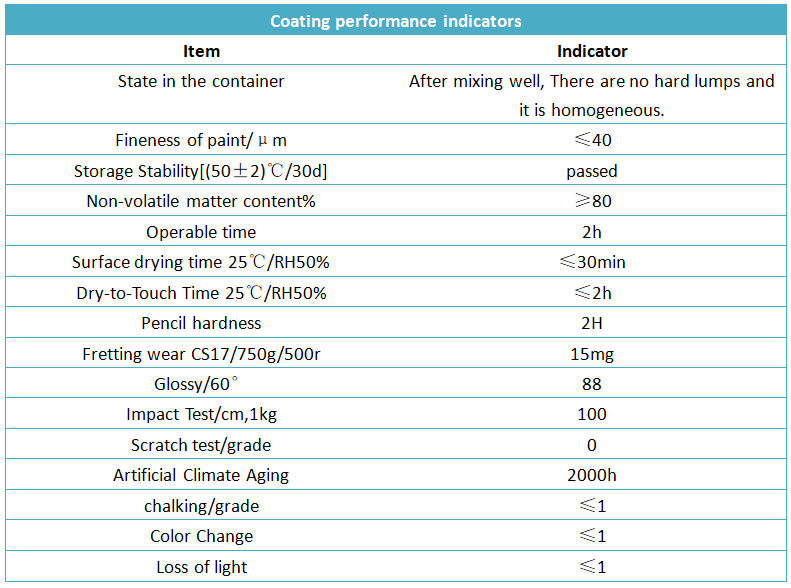

These attributes have been confirmed through experimentation. A coating film was prepared by mixing Zhanxin’s high-solid hydroxyacrylic resin 1753 with Feiyang’s proprietary polyaspartic resin F420 in a specific ratio with HDI trimer. The results validated the performance benefits outlined above.

Test results indicate that polyaspartic resin significantly enhances the solid content, drying speed, and mechanical properties of acrylic polyurethane coatings. Various polyaspartic resin formulations can be blended with hydroxypropyl resin based on specific performance requirements to create coatings with targeted attributes.

This approach is now widely applied in industries such as automotive repair, aviation, heavy machinery, and outdoor steel structures. It has made substantial contributions toward realizing carbon-neutrality goals and fostering a more sustainable future.

Feiyang has been specializing in the production of raw materials for polyaspartic coatings for 30 years and can provide polyaspartic resins, hardeners and coating formulations. Some of our polyaspartic coating formulations: Polyaspartic Coating

Feel free to contact us: marketing@feiyang.com.cn

Our products list: