Feiyang 2023 Polyaspartic Innovations and Latest Application Developments

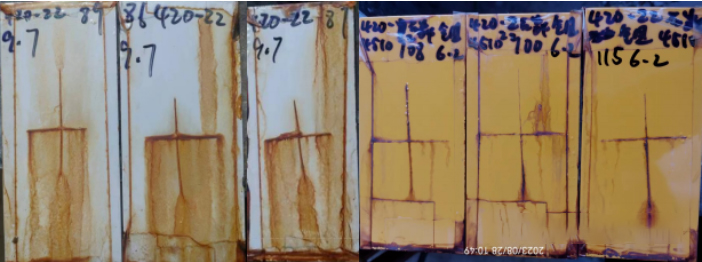

Enhanced Salt Spray Series Products

The focus of the improved salt spray series products is enhancing wet adhesion and increasing the salt spray resistance of polyaspartic polyurea. The modification plan does not introduce groups sensitive to weathering, ensuring good weatherability. Future applications in Direct-To-Metal (DTM) products are expected to be highly anticipated.

Ketimine Series Products

Several ketimine series products have been launched, working on the principle that contact with moisture hydrolyzes to form primary amines, which react rapidly with isocyanates. The absorbed moisture helps maintain the polyaspartic polyurea's pot life, extending the usability of the coating. Ketimines can be incorporated into polyaspartate ester resins or applied alone. Their highlights include viscosity reduction, which balances longer pot life with faster drying times.

90% Solids Polyaspartic Topcoat

To address the issue of outdoor construction avoiding VOC emissions, we introduced a system combining epoxy anti-corrosion primers with up to 90% solids and polyaspartic polyurea topcoats. This system meets environmental, construction convenience, and labor-saving economic requirements in various corrosive environments. In addition to providing solutions for 90% solids polyaspartic polyurea topcoats, we also offer special solvent-free epoxy curing agents. These, when paired with commercially available E51 epoxy resin, allow for the easy development of high-solids epoxy primers with long pot life, suitable for air spray application, and offering excellent anti-corrosion performance.

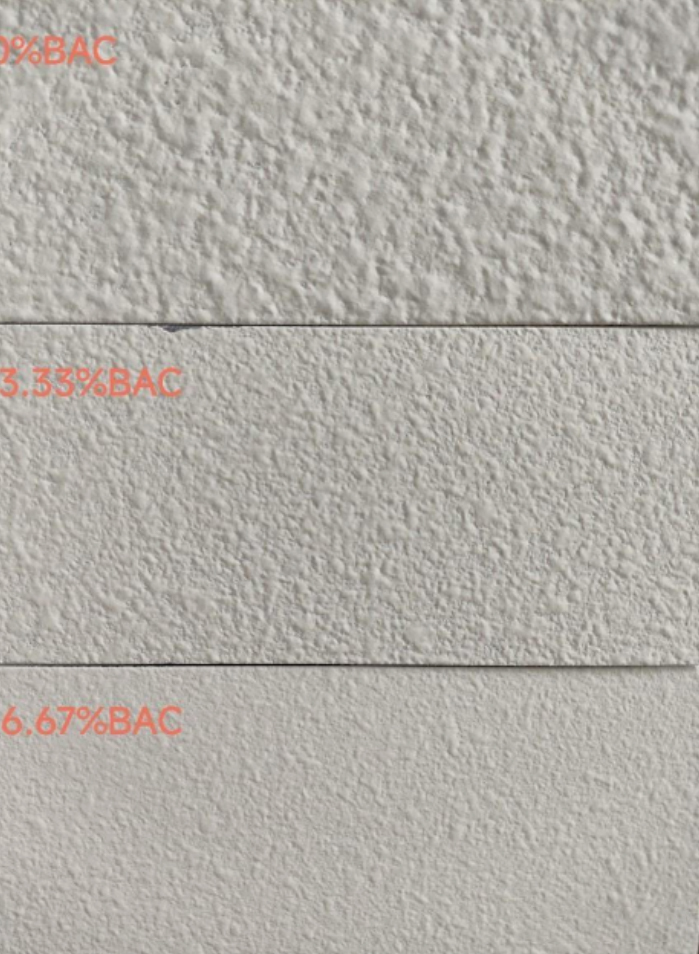

High Solids Orange Peel Paint

Compared to existing products, it nearly doubles the solid content, emits lower VOCs, has a thick paste consistency for easy application of thickness, delivers an excellent orange peel effect, and offers superior corrosion and weather resistance. Most importantly, it eliminates the need for orange peel additives, does not alter surface tension, and does not affect re-coating properties.

High Solids Wind Turbine Blade Topcoat

As part of our green industrial innovation, we introduced a high-solids topcoat solution for wind turbine blades. Its performance aligns with the newly upcoming standards of "Technical Specification for Corrosion Control of Coastal and Offshore Wind Turbine Generators."

More Innovative Applications

In addition, solvent-free wood paints suitable for Class C transport and storage and air spray application, impact-resistant and deformation-resistant solvent-free protective coatings for new energy battery pack water cooling plates, DTM coatings compatible with galvanized substrates for CX corrosion protection levels, DIY tile color change solutions, polyaspartic polyurea armor fiber balancing functionality and fashion, and polyaspartic polyurea joint fillers meeting stringent EC1 plus environmental requirements have also garnered much attention and discussion.

What is EC1 PLUS?

Emicode EC1 PLUS (EC1 PLUS): The highest level in the EMICODE environmental label, introduced in 2010. It describes the technical feasibility limits with very low VOC emissions, imposing stricter and higher requirements than the EC1 category. The test method differs from China’s standards, which test the VOC content and harmful substance content of raw materials. The EC1 standard simulates the human living environment, monitoring the variation of VOCs and harmful substances released from materials over time.

Feiyang has been specializing in the production of raw materials for polyaspartic coatings for 30 years and can provide polyaspartic resins, hardeners and coating formulations. Some of our polyaspartic coating formulations: Polyaspartic Coating

Feel free to contact us: marketing@feiyang.com.cn

Our products list: